In the world of diesel engines, the ICP (Injection Control Pressure) sensor plays a vital role in ensuring your vehicle performs efficiently and reliably. Acting as a central element within the fuel injection system, the ICP sensor monitors oil pressure in the high-pressure circuit and directly communicates this information to the engine control module (ECM). If this crucial sensor begins to malfunction, you may notice a decline in performance or encounter unexpected engine issues. More importantly, overlooking the early warning signs can result in serious engine damage or costly repairs down the line.

Understanding how to tell if ICP sensor is bad is essential for any vehicle owner, enthusiast, or mechanic working with diesel engines. Timely identification and resolution of ICP sensor problems can save you significant time, money, and frustration. In this article, we’ll delve deep into the functions of the ICP sensor, highlight the most common symptoms and causes of failure, and offer actionable guidance on diagnosing and fixing a faulty sensor. By the end, you’ll be well-equipped to keep your vehicle running smoothly and to avoid scenarios where minor sensor issues escalate into major mechanical failures. So, let’s break down the process and help you confidently navigate ICP sensor challenges.

Understanding the ICP Sensor

What Is an ICP Sensor?

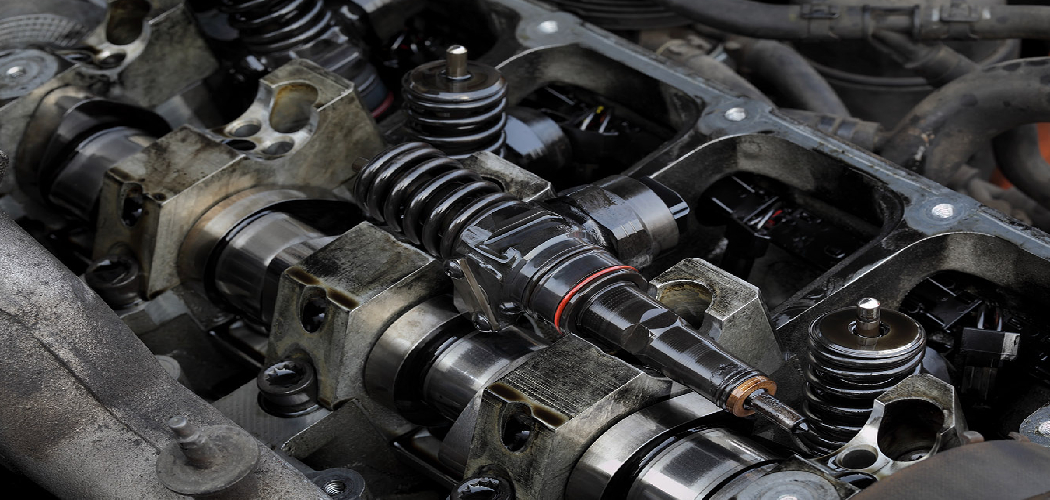

At its core, the ICP sensor is a pressure transducer that sits within the fuel injection system—most commonly found in Ford Powerstroke diesel engines but present in many other makes and models as well. Its primary responsibility is to measure the pressure within the high-pressure oil rail, which is critical for proper fuel delivery. The readings captured by the ICP sensor ensure that the right amount of fuel is injected at the correct pressure to match the engine’s demands in real time.

How It Works in Diesel Engines

Operating at the intersection between mechanical and electronic systems, the ICP sensor’s accurate readings inform the ECM about the current injection pressure. Whenever you accelerate, climb a hill, or tow a heavy load, the ECM adjusts pressure accordingly, guaranteeing optimal performance, emissions control, and fuel efficiency. Without a properly functioning ICP sensor, the entire engine management system can be thrown off balance, leading to performance and drivability issues.

Symptoms of a Bad ICP Sensor

Warning Signs to Look Out For

For most drivers, the initial signs of a failing ICP sensor can be subtle, growing more noticeable over time. One of the most common indicators is a rough or erratic idle; the engine may surge, stumble, or feel unsteady when at rest. Occasionally, stalling can also occur without warning, especially at low speeds or when coming to a stop.

A compromised ICP sensor often impacts fuel efficiency. If you notice your vehicle consuming more diesel than usual without a clear reason, it might be time to investigate. Difficulty starting the engine, such as long crank times or multiple failed attempts, also points to inconsistencies in the required fuel pressure, which may stem from an ICP sensor fault.

Additionally, the check engine light is a critical clue—a faulty ICP sensor will often trigger a diagnostic trouble code (DTC). While a range of engine issues can trigger this warning, its presence alongside the other symptoms strengthens the likelihood of ICP sensor involvement.

Physical Damage to the Sensor

Beyond behavioral clues, a visual inspection can provide more definitive evidence. Physical damage to the sensor itself can include oil leaking from the body or connector, which compromises sensor reliability and can generate false readings. Corrosion or residue buildup, particularly at the electrical connection points, may disrupt communication with the ECM. If you see any signs of oil intrusion or visible deterioration on or around the ICP sensor, it often spells trouble for sensor function and accuracy.

Causes of ICP Sensor Failures

Wear and Tear Over Time

Like any engine component, the ICP sensor is subject to daily stress and wear. As your vehicle ages, the sensor’s internal circuitry and seals degrade naturally from heat, vibration, and repeated cycles of pressure change, which eventually compromise its accuracy and responsiveness.

External Factors

Contaminants from engine oil or debris present in the environment can also hasten ICP sensor failure. Oil contamination is a particular concern since the sensor is constantly exposed to high-pressure oil; dirty or degraded oil increases the risk of clogging and sensor malfunction. Faulty or loose wiring, as well as damaged connectors, can interrupt signal transmission and render the sensor unreliable or unreadable by the ECM.

Impact of Poor Maintenance

Neglecting routine maintenance can accelerate ICP sensor problems. Skipping oil changes or using low-quality oil and filters introduces more contaminants and debris into the system, increasing sensor wear. Those who overlook regular inspections may also miss the early warning signs of sensor damage or electrical connection problems, allowing minor issues to snowball into major repairs down the road.

How to Tell If ICP Sensor Is Bad: Diagnosing a Faulty ICP Sensor

Step-by-Step Diagnostic Process

When trying to determine how to tell if ICP sensor is bad, starting with a systematic diagnostic process ensures accuracy. Begin with a thorough visual check. Look for damaged wiring, broken connectors, or oil leaks around the mounting area. Any obvious defects here will provide direction for further investigation.

Next, utilize a diagnostic scanner compatible with your vehicle’s make and model. Plug the scanner into the OBD-II port and search for any error codes linked to ICP sensor performance or injection pressure irregularities. P2285, P2286, and P2287 are common DTCs associated with ICP sensor malfunctions. If you find relevant error codes, note their frequency and pattern—sporadic codes may suggest intermittent issues like loose connections.

After retrieving error codes, proceed to test the sensor’s electrical output using a multimeter. Disconnect the sensor and measure the reference voltage, signal return, and ground connections against the manufacturer’s specifications. Compare your readings to the expected values; discrepancies indicate a faulty sensor or wiring fault that needs attention.

Common Diagnostic Challenges

Accurately diagnosing ICP sensor failure can be challenging due to symptom overlap with other fuel delivery or pressure regulation components. For instance, a malfunctioning fuel pump or faulty pressure regulator might mimic many of the same issues, including rough idling, stalling, or a drop in engine power. Careful step-by-step elimination of other causes is important before concluding the sensor is to blame. Consulting your vehicle’s service manual or working with an experienced technician can help avoid unnecessary part replacement and troubleshooting errors.

Consequences of Ignoring a Bad ICP Sensor

Affecting Engine Performance

A faulty ICP sensor should never be disregarded. Left unchecked, its inaccurate readings disrupt the ECM’s calculations, leading to poor engine response. Drivers may experience inconsistent power delivery, hesitation during acceleration, or sharp drops in driving smoothness. The vehicle becomes less predictable, which not only makes for an unpleasant experience but can also increase safety risks under certain driving conditions.

Long-Term Impacts

Over time, ignoring a bad ICP sensor amplifies the risk of severe engine issues. Prolonged periods of incorrect injection pressure can cause undue stress on critical components such as the injectors, high-pressure oil rail, and even internal engine parts. What starts as a simple sensor malfunction may escalate into extensive engine damage, requiring major repairs that are both time-consuming and expensive. The cost of delayed intervention can far outweigh the initial expense of replacing the ICP sensor at the first sign of trouble.

Replacing a Faulty ICP Sensor

When to Replace Your ICP Sensor

Determining when replacement is necessary comes down to recognizing persistent symptoms—especially after initial troubleshooting. If the vehicle continues to idle roughly, display the check engine light despite repairs, or fails to maintain consistent fuel pressure, it’s likely time for a new ICP sensor.

DIY Replacement Guide

For the mechanically inclined, replacing an ICP sensor can be a manageable task with some planning and attention to detail. The first step is to locate the ICP sensor, typically found on one of the high-pressure oil rails, accessible either at the front or rear of the engine, depending on your vehicle make. Refer to the service manual for the exact position.

Once located, disconnect the vehicle’s battery. This is crucial to prevent electrical shorts or accidental engagement of the starter motor during the repair process. Carefully unplug the electrical connector from the sensor, taking care not to damage the wires or clip. Using an appropriate socket, loosen the sensor and remove it from the oil rail. When installing the new sensor, avoid over-tightening to prevent cross-threading or damaging the housing.

Reconnect the electrical plug, double-check all connections for security, and finally, reconnect the battery. Starting the engine should clear any related error codes, but some vehicles may require a manual reset of the ECM or a short test drive to allow the computer to adapt to the new component.

Professional Assistance

While many drivers can tackle this replacement themselves, it’s important to recognize when the job exceeds one’s skills or available tools. Complex engine layouts, hard-to-reach mounting points, or persistent issues even after replacement signal it’s time to visit a qualified mechanic. Relying on professional expertise not only ensures the repair is performed correctly but also guards against unintentional damage to adjacent engine parts.

Preventing Future ICP Sensor Issues

Maintenance Best Practices

Proactive care is the best defense against repeat sensor problems. Make a habit of regular engine checks, paying close attention to the oil level, oil condition, and the state of electrical connections. Routine cleaning of the engine bay limits the accumulation of dirt and contaminants that can affect sensor performance and signal transmission.

Tips to Extend Sensor Lifespan

Using only high-quality engine oil and changing it at manufacturer-recommended intervals minimizes sludge formation and contamination. Keeping fuel filters clean and up to date provides an added layer of protection, ensuring no debris or excess moisture reaches sensitive engine components. Monitoring for small leaks early prevents cascading issues, while addressing minor sensor irregularities quickly guides you toward long-term trouble-free operation.

Common Misconceptions About ICP Sensors

There are several widespread myths concerning ICP sensors and their role in engine health. One common misconception is that any engine-related issue—such as rough running, slow starts, or excessive smoking—means the ICP sensor is to blame. In reality, these symptoms can stem from a range of causes, including injector fault, fuel supply problems, or even ECM malfunctions. Another myth is that sensor problems only occur in high-mileage vehicles; in fact, contamination or electrical faults can affect ICP sensors at any stage of operation.

It’s important to rely on sound diagnostic practices rather than guesswork. Understanding precisely how the ICP sensor functions and being able to distinguish its specific failure symptoms not only saves time and money but also prevents unnecessary parts replacement.

Benefits of Understanding ICP Sensor Issues

Becoming familiar with how to tell if ICP sensor is bad delivers a host of practical advantages. Firstly, it allows for faster fault resolution and minimization of vehicle downtime—a benefit for personal, commercial, and fleet vehicles alike. Being able to recognize symptoms and either perform repairs or communicate effectively with a mechanic helps avoid cascading engine issues, which can otherwise result in sky-high repair bills and lost productivity.

Additionally, proactive attention to sensor health boosts overall vehicle performance, improves fuel efficiency, and extends engine life. By catching issues early, you maintain your diesel engine’s reputation for reliability and get the most value from every maintenance dollar invested.

Conclusion

Recognizing how to tell if ICP sensor is bad is a fundamental skill for anyone responsible for diesel engine maintenance and operation. By understanding its behaviors, causes of failure, and diagnostic methods, you empower yourself to spot early warning signs and act swiftly to correct them. This approach not only safeguards your engine against costly damage but also ensures efficient, trouble-free vehicle performance for the long haul.

Whenever you encounter rough idling, stalling, poor fuel efficiency, or a persistent check engine light, consider the ICP sensor as part of your troubleshooting routine. Use step-by-step diagnosis and, if necessary, replace the sensor promptly to prevent escalating engine problems. Through diligent care, informed decisions, and a solid grasp of how to tell if an ICP sensor is bad, you set your vehicle up for maximum longevity and reliability on every journey.