The Anti-Lock Brake System (ABS) is a crucial safety feature in modern vehicles, designed to prevent wheel lock-up during hard braking and maintain control on slippery surfaces.

However, like any system in a vehicle, the ABS can occasionally experience issues that require resetting. Understanding how to safely and effectively reset the ABS can help ensure your vehicle operates smoothly and enhances your driving safety. This guide will walk you through the steps of how to reset anti lock brake system.

Common Reasons ABS Warning Light Turns On

The ABS warning light on your dashboard can illuminate for several reasons, signaling potential issues with the system. Here are some common causes:

- Faulty Wheel Speed Sensors

ABS relies on wheel speed sensors to monitor the rotational speed of each wheel. If one or more sensors are damaged or dirty, they may send incorrect data to the ABS control module, triggering the warning light. - Low Brake Fluid Levels

Insufficient brake fluid can reduce the hydraulic pressure required for the ABS to function properly. A low fluid level is often caused by a leak or worn brake pads. - Malfunctioning ABS Module

An issue with the ABS control module, often due to electrical problems like corrosion or a damaged wiring harness, can prevent the system from operating as intended. - Blown Fuse

If the fuse linked to the ABS system blows, it disrupts the electrical supply, prompting the warning light to turn on. - Worn Hydraulic Pump

The hydraulic pump plays a critical role in maintaining pressure in the ABS. Over time, wear and tear can cause the pump to weaken or fail, triggering the alert.

Understanding the potential causes behind the ABS warning light can help you pinpoint and address the issue, ensuring your braking system remains reliable and efficient.

Safety Precautions Before Resetting ABS

Resetting the ABS warning light should only be done after addressing the root cause of the issue. Taking proper safety precautions is essential to ensure both your safety and the optimal functionality of the braking system. Here are the key precautions to follow:

- Confirm Diagnosis – Always verify the underlying problem causing the ABS warning light. Use a diagnostic tool or consult a professional mechanic to identify and resolve any faults before attempting a reset.

- Disconnect the Battery – Before working on electrical components, disconnect the negative terminal of the car battery to prevent accidental short circuits or electrical mishaps.

- Ensure the Vehicle is Stationary – Make sure the car is parked on a flat, stable surface with the parking brake engaged to avoid unintended movement during the process.

- Inspect Brake Fluid Levels – Check that the brake fluid levels are within the recommended range. Refilling or replacing brake fluid may be necessary if it is low or degraded.

- Wear Protective Gear – Use gloves and safety goggles to protect yourself while working around the vehicle’s electrical and braking systems.

- Follow Manufacturer Guidelines – Always refer to the vehicle’s manual for specific instructions related to the ABS system and its components.

By adhering to these precautions, you can safely proceed with resetting the ABS warning light while maintaining the integrity of your braking system.

10 Methods How to Reset Anti Lock Brake System

Method 1: Ensure Vehicle Safety and Readiness

Before attempting to reset the ABS system, ensure the vehicle is parked on a flat surface with the parking brake engaged. Turn off the ignition and remove the key.

Disconnecting or working on ABS components while the engine is running can trigger electrical shorts or false sensor readings. Additionally, make sure you have the necessary tools, including a wrench, screwdriver, and possibly a diagnostic scanner. Preparing the vehicle and workspace ensures a safe and efficient reset process.

Method 2: Check Wheel Speed Sensors

ABS systems rely on wheel speed sensors at each wheel to monitor rotation and prevent skidding. A common cause of an ABS warning light is dirt, debris, or damage to these sensors. Inspect each sensor for visible contamination, corrosion, or broken wires.

Clean the sensor tips with a soft cloth or mild cleaner, and ensure that the connectors are securely attached. Properly functioning wheel speed sensors are crucial for the ABS system to operate correctly, and clearing sensor issues often resolves warning light problems.

Method 3: Check and Clean the Tone Rings

The tone rings, also called reluctor rings, work with the wheel speed sensors to detect wheel rotation. Over time, dirt, rust, or debris can accumulate on the rings, causing false ABS readings. Inspect the tone rings on each wheel, and carefully clean them using a brush or soft cloth.

Avoid using abrasive materials that could damage the ring. Ensuring clean tone rings can eliminate false error codes and allow the ABS system to function properly, sometimes clearing the need for a manual reset.

Method 4: Inspect Brake Fluid Levels and Condition

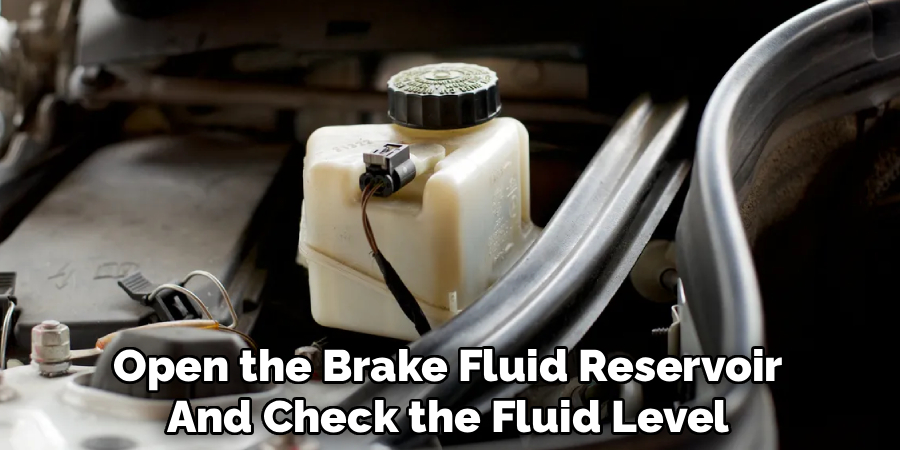

Low or contaminated brake fluid can trigger ABS warnings. Open the brake fluid reservoir and check the fluid level, ensuring it is within the recommended range. Also, inspect the fluid’s condition; dark, dirty fluid may require a brake system flush.

Top off the fluid with the manufacturer-recommended brake fluid type if necessary. Maintaining proper fluid levels ensures hydraulic pressure to the braking system and can sometimes reset the ABS if low fluid caused the warning light.

Method 5: Disconnect the Battery Temporarily

One method of resetting the ABS system is to temporarily disconnect the vehicle battery. Turn off the ignition and remove the negative battery cable. Wait approximately 10–15 minutes to allow residual electrical charge to dissipate, which clears stored ABS fault codes.

Reconnect the battery and turn the ignition on to check if the ABS warning light is cleared. This method is effective for minor glitches or temporary electrical errors but may require recalibration of some vehicle systems afterward.

Method 6: Use an OBD-II Scanner

A professional and reliable method to reset the ABS system is using an OBD-II (On-Board Diagnostics) scanner. Connect the scanner to the vehicle’s OBD-II port, usually located under the dashboard. Follow the scanner prompts to read ABS fault codes and then clear or reset them.

Using a diagnostic tool not only clears the warning light but also provides insight into potential underlying issues that may need repair. This method is the most precise way to ensure that the ABS system resets correctly without masking genuine problems.

Method 7: Perform a “Drive Cycle” Reset

Some vehicles allow ABS system reset through a drive cycle procedure. This involves starting the vehicle, driving at a specific speed, and performing gentle braking to allow the system to recalibrate its sensors and relearn wheel speed baselines.

Consult the vehicle’s service manual for manufacturer-specific instructions on speed ranges, braking duration, and surface conditions. Completing the drive cycle can reset minor ABS errors and recalibrate the system without using electronic tools.

Method 8: Check ABS Fuses and Relays

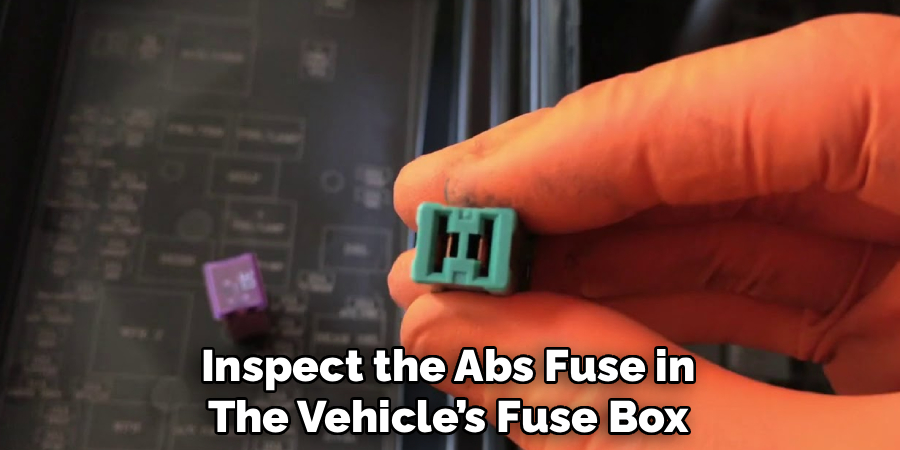

ABS systems include dedicated fuses and relays that control electrical flow. Inspect the ABS fuse in the vehicle’s fuse box for damage or blown connections. Check the ABS relay for proper operation and replace it if necessary.

Faulty fuses or relays can trigger ABS warning lights and prevent the system from functioning correctly. Replacing these components may restore proper electrical continuity and clear ABS fault codes, eliminating the need for further reset steps.

Method 9: Examine ABS Module Connections

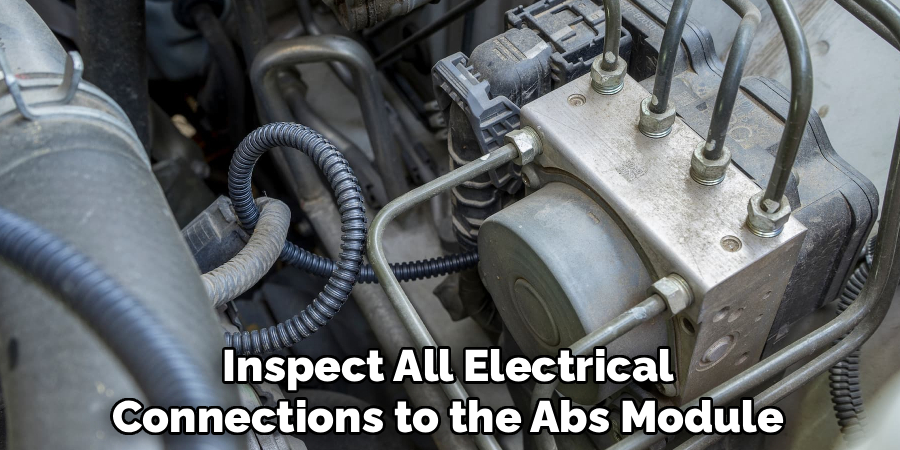

The ABS control module coordinates signals between wheel speed sensors, the hydraulic control unit, and the vehicle’s onboard computer. Loose or corroded wiring can cause false ABS warnings. Inspect all electrical connections to the ABS module, ensuring they are secure and free of corrosion.

Clean any corroded terminals with an electrical contact cleaner and reconnect them tightly. Proper connection of the ABS module often resolves electronic glitches, allowing the system to reset automatically.

Method 10: Professional Inspection and Recalibration

If the ABS warning light remains on after completing the previous steps, it is essential to consult a qualified mechanic or dealership service.

Persistent ABS faults may indicate damaged sensors, hydraulic issues, or internal module failure. A professional can perform an in-depth diagnostic, replace damaged components, and recalibrate the ABS system using specialized equipment. Professional recalibration ensures the system operates safely and prevents potentially dangerous braking issues.

Conclusion

Resetting an Anti-Lock Brake System requires a combination of careful inspection, minor maintenance, and, in some cases, electronic diagnostics. By following these ten methods—from ensuring vehicle safety, checking sensors, tone rings, and brake fluid to using OBD-II scanners and professional recalibration—you can address ABS warnings effectively.

Proper attention to detail during reset procedures ensures the ABS system functions correctly, maintaining vehicle safety, optimal braking performance, and peace of mind. While some resets can be performed at home, persistent or complex issues should always be handled by trained professionals to guarantee safe operation.

Follow these simple instructions outlined in this blog post about how to reset anti lock brake system, and you’ll be able to get the job done with ease.

About

Safety Fic is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of diy, Safety Fic delves into the art and science of Safety Fic-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Safety Fic) Focus on sustainable design, industry-driven projects, and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in diyfastly.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Safety Fic his insights on indoor design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.