The GM impact sensor, also known as the airbag crash sensor, is an essential safety component in General Motors vehicles. It detects sudden deceleration or collisions and sends a signal to deploy airbags, protecting passengers during an accident. A malfunctioning sensor can compromise airbag deployment, putting occupants at risk.

Regular inspection and testing of the impact sensor ensures that your vehicle’s airbag system functions correctly. Understanding how to check gm impact sensor, recognize warning signs, and perform basic diagnostics can prevent costly repairs and enhance safety for you and your passengers.

Why Check a GM Impact Sensor?

1. Ensure Airbag Functionality

The primary purpose of an impact sensor is to detect collisions and trigger the airbags. A malfunctioning sensor can prevent airbags from deploying during an accident, putting vehicle occupants at serious risk. Regular checks ensure the sensor will function correctly when needed.

2. Identify Early Malfunctions

Sensors can develop faults due to corrosion, wiring damage, or internal failures. Detecting these issues early through testing prevents unexpected failures and avoids triggering false airbag warnings.

3. Maintain Dashboard Warning Systems

A faulty impact sensor often illuminates the airbag warning light. Checking the sensor allows you to correct the issue, ensuring that warning systems provide accurate information and you can trust alerts for other vehicle systems.

4. Compliance with Safety Standards

Vehicles are required to meet strict safety regulations. Regularly checking the impact sensor helps maintain compliance and ensures your vehicle is safe for passengers and meets legal safety requirements.

5. Prevent Costly Repairs

Ignoring a faulty sensor can lead to unnecessary airbag deployments, damage to the airbag module, or other related electrical issues. Early detection and testing prevent costly repairs or replacements.

Tools and Materials You’ll Need

- Digital multimeter or OBD-II scanner

- Vehicle repair manual (specific to your GM model)

- Socket and ratchet set

- Screwdriver set

- Safety gloves

- Safety goggles

- Flashlight

- Torque wrench (optional)

- Clean cloth or rag

- Battery terminal wrench (for disconnecting the battery)

10 Step-By-Step Guidelines on How to Check GM Impact Sensor

Step 1: Ensure Vehicle Safety

Before starting, park the vehicle on a flat surface, engage the parking brake, and turn off the ignition. Disconnect the battery to prevent accidental airbag deployment during inspection.

Handling impact sensors requires extreme caution. Disconnecting the battery prevents electrical shorts and ensures your safety while accessing the sensor. Always wait 10–15 minutes after disconnecting the battery before touching the airbag system components.

Step 2: Locate the Impact Sensor

Refer to your vehicle manual to locate the GM impact sensor. Most are positioned near the front or sides of the vehicle, usually behind the bumper or within the engine bay, and connected to the airbag control module.

Identifying the correct sensor is crucial. Confusing it with other sensors in the vicinity can lead to misdiagnosis or accidental damage to the airbag system. Use a flashlight for better visibility in tight spaces.

Step 3: Inspect the Sensor Visually

Check the sensor for any signs of physical damage, corrosion, or loose connections. Look for frayed wires, bent terminals, or cracks in the housing that could impair functionality.

Even minor damage can affect the sensor’s performance. Cleaning connectors with a rag and ensuring proper alignment reduces the risk of false readings and ensures a secure fit.

Step 4: Check Wiring and Connectors

Use a multimeter to verify continuity in the sensor wiring. Disconnect the sensor connector and test each wire for resistance, continuity, or shorts according to the vehicle’s service manual specifications.

Proper wiring is critical for the sensor to transmit accurate signals to the airbag module. Damaged wiring or loose connectors can trigger airbag warning lights or prevent deployment during a collision.

Step 5: Scan for Airbag Codes

Connect an OBD-II scanner to the vehicle’s diagnostic port and read any stored codes related to the airbag system. Common codes include B0010, B0020, or B0051, indicating potential sensor issues.

Clearing existing codes and monitoring real-time data can help determine if the sensor is functioning correctly or if replacement is necessary. Record all codes before clearing to track recurring problems.

Step 6: Test Sensor Resistance

Set your multimeter to the ohms setting and measure the sensor’s resistance across the specified terminals. Compare readings with manufacturer-recommended values provided in the service manual.

A reading outside the specified range usually indicates a faulty sensor. Accurate resistance testing ensures the sensor can reliably detect impacts and communicate with the airbag system.

Step 7: Test Sensor Voltage

Reconnect the sensor and turn the ignition to the “ON” position without starting the engine. Measure the voltage supplied to the sensor and ensure it matches the expected values.

Voltage testing confirms the sensor is receiving adequate power. Low or fluctuating voltage could indicate wiring problems or a failing sensor, requiring further inspection or replacement.

Step 8: Perform Functional Simulation (If Safe)

Some GM vehicles allow safe functional testing using specialized scan tools or simulators. This involves applying controlled signals to see if the sensor responds correctly without deploying the airbag.

Functional simulation should be performed cautiously. Refer to the vehicle’s service manual or use professional equipment to prevent accidental airbag deployment. This step verifies sensor performance under simulated conditions.

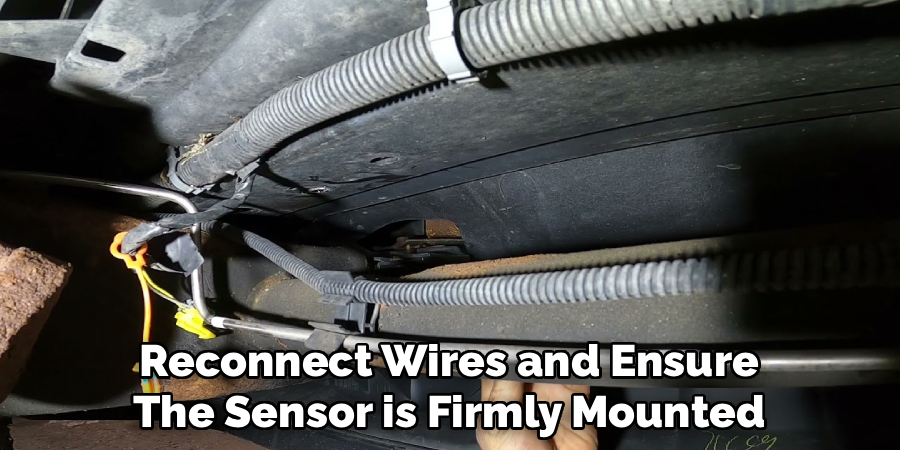

Step 9: Reassemble and Secure Sensor

Once testing is complete, reconnect any disconnected wires and ensure the sensor is firmly mounted. Secure the battery terminals and replace any covers or brackets removed during inspection.

Proper reassembly is critical to maintain sensor alignment and system integrity. Loose or misaligned sensors may fail to detect impacts or trigger false warnings.

Step 10: Final Verification

Reconnect the battery, start the vehicle, and check for airbag warning lights on the dashboard. If the sensor is functioning correctly, the airbag light should turn off after the system completes its self-check.

Drive the vehicle briefly in a safe area to confirm normal operation. Persistent warning lights indicate further diagnostics or replacement may be needed. Ensuring the system works before driving is essential for passenger safety.

Following these steps on how to check gm impact sensor, you should now have a good understanding of how the impact sensor works and how to check for proper operation. It is important to regularly test and maintain your vehicle’s safety features to ensure they are functioning correctly in the event of an accident.

Additional Tips

- Always wear safety gloves and goggles when working around the airbag system.

- Follow the manufacturer’s service manual closely for sensor location and specifications.

- Label connectors and wires to avoid mistakes during reassembly.

- Use a multimeter and scan tool for accurate readings rather than relying on visual inspection alone.

- Disconnect the battery and wait before touching any airbag-related components.

- Document all steps for future reference or troubleshooting.

- Avoid jarring the vehicle while the battery is disconnected, as some sensors are sensitive to shocks.

Common Mistakes to Avoid

- Attempting to test the sensor with the battery connected, risking accidental airbag deployment.

- Ignoring manufacturer specifications for resistance and voltage readings.

- Mishandling connectors or wires can cause permanent damage.

- Overlooking corrosion or physical damage during visual inspection.

- Failing to clear codes or check airbag warning lights after testing.

Do You Need To Use Professionals?

While basic visual inspection and multimeter tests can be performed by a knowledgeable DIYer, consulting a professional is recommended for comprehensive testing. Professionals have specialized tools and simulators to safely test impact sensors without risking airbag deployment.

Complex cases such as multiple sensor faults, wiring issues, or integration with the vehicle’s safety system require professional expertise. A certified technician can diagnose hidden issues, replace faulty sensors, and ensure the airbag system functions reliably.

Even experienced DIYers should be cautious; airbag systems are critical safety components, and errors during testing or installation can have serious consequences. Professionals provide peace of mind and safety assurances.

Frequently Asked Questions

Q1: How Can I Tell If My GM Impact Sensor Is Faulty?

A1: Warning lights on the dashboard, especially the airbag light, indicate a potential sensor issue. Diagnostic trouble codes from an OBD-II scanner can confirm the problem. Other signs include airbag system errors during self-checks or unusual dashboard behavior.

Q2: Is It Safe To Test the Sensor Myself?

A2: Basic visual inspections and multimeter testing are generally safe if the battery is disconnected. Avoid applying power or physically impacting the sensor, as this can trigger the airbag. Always follow safety protocols outlined in the service manual.

Q3: Can a Faulty Sensor Prevent Airbags From Deploying?

A3: Yes, a malfunctioning impact sensor can prevent the airbag system from recognizing a collision, delaying or stopping deployment. This can significantly increase the risk of injury during an accident, making timely inspection and replacement essential.

Q4: How Often Should I Check the Impact Sensors?

A4: Regular inspection is recommended whenever the airbag warning light is illuminated or after accidents, collisions, or electrical work near the sensor. Many manufacturers suggest a periodic check during routine vehicle maintenance or every few years for older vehicles.

Conclusion

Checking a GM impact sensor is an essential maintenance task to ensure your airbag system functions correctly. By following step-by-step guidelines on how to check gm impact sensor, using proper tools, and taking safety precautions, you can assess the sensor’s condition and address issues before they compromise safety.

Proper inspection, testing, and maintenance enhance vehicle safety, prevent airbag malfunctions, and ensure compliance with safety standards. Whether performed as a DIY project or by a professional, regular impact sensor checks provide peace of mind and protect the lives of passengers during accidents.

About

Safety Fic is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of diy, Safety Fic delves into the art and science of Safety Fic-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Safety Fic) Focus on sustainable design, industry-driven projects, and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in diyfastly.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Safety Fic his insights on indoor design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.