Safety glass is a type of glass specifically designed to reduce the risk of injury when shattered. Unlike regular glass, safety glass is manufactured using advanced processes that enhance its strength and durability. It is commonly used in automobiles, buildings, and various other applications where increased safety and protection are essential.

This introduction will guide you through how to make safety glass shatterproof, ensuring its reliability and effectiveness in critical situations.

What is Safety Glass?

Safety glass is a specialized glass designed to prioritize safety by reducing the risk of injury upon impact or breakage. It achieves this through distinct manufacturing techniques that either prevent the glass from shattering into sharp, dangerous shards or significantly increase its strength against breaking. Types of safety glass include tempered glass, which is heat-treated to create greater resilience,

and laminated glass, which incorporates a layer of plastic or resin between two sheets of glass. These properties make safety glass an ideal choice for applications such as automotive windshields, protective barriers, and building windows, where durability and safety are paramount.

Why Making Safety Glass Shatterproof

Making safety glass shatterproof is crucial for minimizing injuries and enhancing protection in various settings. When traditional glass breaks, it shatters into sharp, jagged pieces that can cause severe harm. Shatterproof safety glass, on the other hand, is designed to either remain intact or break into small, less dangerous fragments, significantly reducing the risk of injury.

This durability is particularly vital in high-impact environments, such as car windshields or buildings in areas prone to natural disasters, where structural integrity can be lifesaving. Additionally, shatterproof glass provides peace of mind, ensuring that individuals and property are better protected in unexpected accidents or emergencies.

10 Methods How to Make Safety Glass Shatterproof

1. Heat Tempering

Heat tempering is one of the most common methods used to make safety glass shatterproof. In this process, the glass is heated to a high temperature, typically around 600-700°C, and then rapidly cooled using a controlled air blast. This creates a balance of internal stresses, making the glass much stronger than untreated glass. When tempered glass breaks,

it shatters into small, blunt-edged fragments instead of sharp shards, reducing the risk of injury. This method is widely used in automobile windows, shower doors, and glass tabletops.

2. Laminating with Polyvinyl Butyral (PVB)

Laminated glass is created by sandwiching a thin layer of polyvinyl butyral (PVB) between two sheets of glass. The assembly is then heated and pressurized to bond the layers together. This process enhances the strength of the glass and ensures that if it breaks, the shards adhere to the PVB layer, preventing them from scattering. Laminated glass is commonly used in windshields, skylights,

and storefronts where safety is paramount. Additionally, it provides added benefits like sound insulation and UV protection.

3. Using Chemically Strengthened Glass

Chemical strengthening involves immersing the glass in a bath of molten potassium nitrate. During this process, smaller sodium ions in the glass surface are replaced by larger potassium ions, creating a layer of compressive stress. This strengthens the glass and makes it more resistant to impact and scratches. Chemically strengthened glass is thinner and lighter than tempered glass,

making it ideal for applications like smartphones, aircraft windows, and advanced architectural designs.

4. Adding an Anti-Shatter Film

Applying an anti-shatter film to the surface of the glass is a straightforward method to enhance its safety. The film, usually made of polyester, is adhered to the glass surface, forming a protective layer that holds the shards together if the glass breaks. Anti-shatter films are commonly used in residential and commercial windows to provide an added layer of security against break-ins,

accidents, and even explosions. They are also a cost-effective solution for retrofitting existing glass installations.

5. Embedding a Wire Mesh

Wire glass is created by embedding a wire mesh within the glass during the manufacturing process. The wire mesh holds the fragments together when the glass breaks, preventing them from falling apart. While not as strong as tempered or laminated glass, wire glass is still effective for specific applications, such as fire-rated doors and windows. Its ability to withstand high temperatures makes it particularly useful in fire safety contexts.

6. Applying Ionoplast Interlayers

Ionoplast interlayers, such as SentryGlas®, offer a high-strength alternative to traditional PVB layers. These interlayers are more rigid and durable, providing enhanced impact resistance and clarity. They are particularly beneficial in architectural applications like glass railings, balustrades, and hurricane-resistant windows. By bonding tightly to the glass layers, ionoplast interlayers ensure that the structure remains intact even under extreme stress.

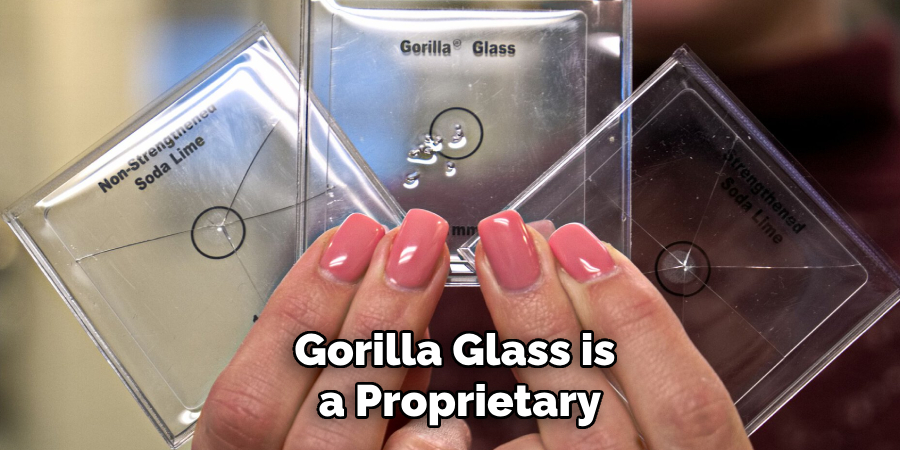

7. Incorporating Gorilla Glass

Gorilla Glass is a proprietary type of chemically strengthened glass developed for high-performance applications. It undergoes a chemical tempering process that makes it incredibly tough and scratch-resistant. Although it is primarily used in electronic devices like smartphones and tablets, its lightweight and durable properties make it a promising material for automotive and architectural uses where weight reduction is critical.

8. Using Ballistic-Grade Glass

Ballistic glass, or bulletproof glass, is designed to withstand high-impact forces from projectiles. It is made by layering multiple sheets of glass and polycarbonate or other plastics. The combination of materials absorbs the energy of the impact and prevents penetration. Ballistic-grade glass is used in security applications such as banks, government buildings, and armored vehicles.

Though it is more expensive and heavier than other safety glass types, it provides unparalleled protection.

9. Reinforcing with Advanced Composites

Advanced composite materials, such as carbon fiber or nanotechnology-enhanced films, can be incorporated into glass to improve its strength and shatter resistance. These materials distribute stress more evenly across the surface of the glass, reducing the likelihood of failure under impact. Composite-reinforced glass is an emerging technology with applications in aerospace, defense, and high-end architecture, where safety and performance are critical.

10. Manufacturing Double-Glazed Safety Glass

Double-glazed safety glass consists of two panes of glass separated by an air or gas-filled space. Each pane can be individually treated with techniques like tempering or lamination to enhance its safety properties. The gap between the panes provides additional insulation against heat and noise, while the dual-layer design increases impact resistance.

Double-glazed safety glass is commonly used in energy-efficient buildings, offering both safety and environmental benefits.

Things to Consider When Choosing Safety Glass

Selecting the right type of safety glass involves evaluating several key factors to ensure optimal performance and suitability for the intended application. Here are some considerations to keep in mind:

- Application Requirements

Determine the specific purpose of the safety glass. For example, automobile windshields typically require laminated glass for enhanced safety, whereas smartphone screens benefit from chemically strengthened glass like Gorilla Glass. Understanding the application helps narrow down the options.

- Level of Protection Needed

Assess the level of impact resistance or protection required. For high-security environments, ballistic-grade glass may be necessary, while residential windows might only require anti-shatter film or tempered glass.

- Environmental Conditions

Consider the operating environment, such as exposure to drastic temperature changes, moisture, or UV radiation. Laminated glass offers UV protection, while wire glass is better suited for fire-rated applications.

- Thickness and Weight Constraints

For projects where weight or space is a concern, such as in smartphone manufacturing or architectural designs, options like chemically strengthened glass or composite-reinforced glass may be more practical.

- Aesthetic and Optical Clarity

For applications like storefronts or glass railings, the clarity and appearance of the glass are critical. Technologies such as ionoplast interlayers can provide a high degree of transparency while maintaining strength.

Common Mistakes to Avoid

When selecting and using safety glass, it’s important to avoid some common mistakes that can compromise performance, safety, and longevity. Here are a few pitfalls to watch out for:

- Choosing the Wrong Type of Glass

Using the incorrect type of safety glass for an application can lead to suboptimal results or even safety hazards. For example, installing tempered glass in a fire-rated door might fail to meet fire safety standards, where wire glass would be more appropriate.

- Overlooking Environmental Factors

Failure to account for environmental conditions, such as exposure to extreme temperatures, humidity, or UV light, can cause the glass to degrade faster. For instance, standard laminates may yellow or weaken under prolonged UV exposure if not properly treated.

- Ignoring Weight and Thickness Requirements

Neglecting weight or space constraints can result in impractical or unsafe installations. Glass that is too heavy for its supporting structure may cause issues, particularly in architectural or automotive applications.

- Underestimating Impact Resistance Needs

Installing glass with insufficient impact resistance for a specific application can lead to breakage and injury. For example, using standard tempered glass instead of ballistic-grade glass in high-security environments would be inadequate.

Conclusion

Safety glass is an essential innovation that has transformed modern industries by enhancing the durability, functionality, and safety of glass installations. From smartphones and automobiles to architectural designs and high-security environments, the variety of safety glass options available today makes it possible to meet specific application demands with precision. Thanks for reading, and we hope this has given you some inspiration on how to make safety glass shatterproof!