A quiet garage door reduces noise pollution and maintains a peaceful living environment. Often, noisy garage doors can disrupt the tranquility of a home, especially if the garage is attached to or near living spaces. Common reasons why garage doors become noisy include rusty hinges, worn-out rollers, and loose hardware, which can cause irritating squeaks and rattles each time the door is opened or closed.

In this article, we will explore practical tips on how to quiet a garage door. The steps covered will include inspecting and identifying noisy components, lubricating moving parts, tightening loose hardware, replacing worn-out rollers, installing anti-vibration pads, insulating the garage door, and maintaining regular servicing. By following these steps, homeowners can significantly reduce their garage door’s noise, creating a quieter and more comfortable environment for everyone.

Inspecting and Identifying Noisy Components

Understanding the different parts of a garage door system is crucial for diagnosing noise issues effectively. A typical garage door setup includes springs, rollers, hinges, tracks, and cables, all of which must work harmoniously for smooth operation. Springs can be torsion or extension, which are vital in balancing the door’s weight. Rollers glide along the tracks, enabling the door to move up and down, while hinges connect the door panels and facilitate bending as the door opens and closes.

To identify specific components that may be causing noise, start by listening carefully as the door operates. Rusty hinges often creak, while worn-out rollers might squeal or grind. Loose parts, such as bolts, nuts, or screws, can lead to rattling noises. Visual inspection is equally important; look for any signs of rust, cracks, flat spots on rollers, or any misalignment in the track.

Damaged cables or frayed wires should also be noted, as they may impact the door’s smooth function. Addressing these issues promptly can significantly reduce the overall noise, providing a quieter garage environment.

How to Quiet a Garage Door: Lubricating Moving Parts

Lubricating the moving parts of your garage door is essential for reducing friction and noise, ensuring smooth and quiet operation. Over time, the components of a garage door system can accumulate dirt and become worn, leading to increased friction, which subsequently results in noisy operation. Regular lubrication reduces noise and protects against rust and corrosion, thereby extending the garage door’s lifespan.

When choosing the right lubricant for garage door components, it is important to opt for silicone- or lithium-based lubricants. These types are superior to products like WD-40, which is primarily a degreaser rather than a lubricant. Silicone-based lubricants are particularly effective for parts made of plastic or nylon. In contrast, lithium-based lubricants are ideal for metal components because they can withstand high pressure and temperature without breaking down.

Follow this step-by-step guide to effectively lubricate garage door hinges, rollers, springs, and tracks:

- Cleaning Dirt and Debris: It is crucial to clean the components properly before applying any lubricant. Use a rag or a small brush to remove dirt, dust, and old grease from the hinges, rollers, springs, and tracks.

- Applying Lubricant Sparingly: The lubricant sparingly ensures all parts are adequately covered without excess dripping. Start with the hinges, applying a small amount of lubricant at the pivot points connecting to the door panels.

- Lubricating the Rollers: For the rollers, place a drop of lubricant on the ball bearings inside the roller’s housing. Avoid lubricating the roller tracks directly, as this can attract dust and debris, leading to further issues.

- Springs and Bearings: Next, focus on the springs. Apply a silicone-based spray or lithium grease along the length of the torsion or extension springs. Also, lubricate any bearings or pulleys involved in the door’s operation.

- Tracks and Additional Components: While it is generally unnecessary to lubricate the tracks, you should still wipe them clean to ensure smooth roller movement. Finally, lubricate any other moving parts, such as the armbar and lock mechanism, to complete the process.

By following these steps, you can maintain the optimal function of your garage door, resulting in a quieter, more efficient system.

How to Quiet a Garage Door: Tightening Loose Hardware

Over time, the vibrations and constant movement of a garage door can cause bolts, nuts, and screws to loosen, which can lead to an increase in noise and reduce the efficiency of the door system. Tightening loose hardware is a crucial step in how to quiet a garage door.

Start by inspecting all the hardware associated with the garage door, including the bolts, nuts, and screws that secure the hinges, rollers, tracks, and other components. Pay close attention to the tracks on either side of the door, as well as the brackets attached to the walls and ceiling. Loose or unevenly fastened hardware can cause the door to rattle or produce excessive vibration as it operates.

To tighten the hardware, use a wrench or screwdriver, depending on the type of fasteners used. Begin at the top of the door and work your way down, ensuring each bolt, nut, and screw is securely fastened. Be careful not to over-tighten, as this can strip the threads or damage the components. At the same time, ensure that all parts are properly aligned, check the tracks for straightness, and make sure the rollers are seated correctly.

By meticulously tightening all the hardware, you significantly reduce unwanted noise and ensure the different components work harmoniously, leading to smoother and quieter garage door operation. Regularly checking and tightening the hardware will also prolong the lifespan of the garage door system, making it a valuable part of your maintenance routine.

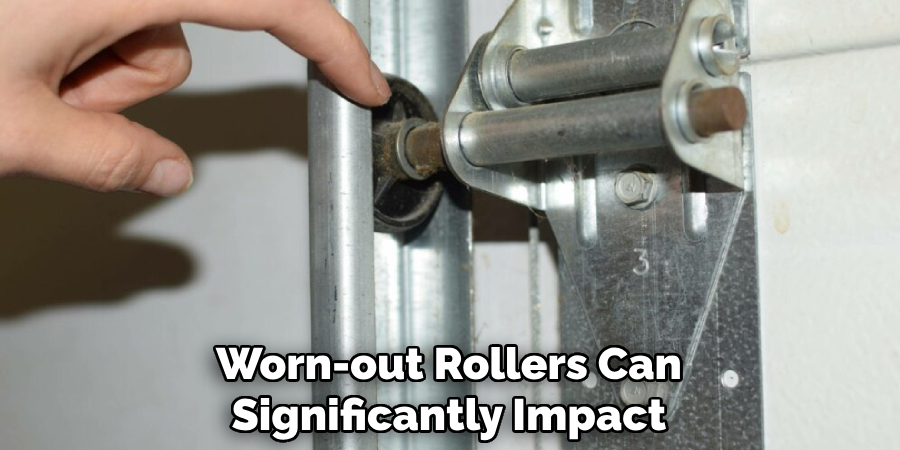

Replacing Worn-out Rollers

Worn-out rollers can significantly impact the performance of your garage door, leading to increased noise and inefficient operation. Common signs that your rollers need replacement include visible cracks, flat spots, or excessively noisy movement. If you notice any of these issues, it’s time to consider new rollers to restore smooth functionality.

When choosing replacement rollers, you have several options: nylon, steel, or quiet rollers. Nylon rollers are popular due to their quiet operation and durability, whereas steel rollers are known for their strength and longevity. Quiet rollers, often made with ball bearings encased in nylon, offer the best of both worlds – they combine steel’s strength with nylon’s noise reduction.

Here is a step-by-step guide to replacing your garage door rollers:

- Securing the Door in Place: First, ensure the garage door is closed. Use a clamp or a C-clamp to secure the door to the track, preventing it from moving while you work.

- Releasing Tension on the Springs: If your garage door uses torsion springs, it is crucial to release the tension to avoid injury. Utilize winding bars and follow proper procedures to reduce spring tension safely.

- Removing Old Rollers: Start by loosening the hinge bolts that hold the rollers in place. Carefully slide the hinge and roller out from the track. Inspect the hinges for any wear or damage and replace if necessary.

- Installing New Rollers: Insert the new rollers into the hinges and guide them back into the track. Re-secure the hinge bolts tightly but avoid over-tightening, which could damage the door or the roller.

- Testing the Door’s Operation: Once all rollers are replaced, remove the clamps from the door. Carefully restore the tension on the springs if applicable. Open and close the garage door several times to ensure it operates smoothly and quietly.

By following these steps, you can effectively replace worn-out rollers, enhancing the performance and longevity of your garage door system while minimizing noise. Regularly inspecting and replacing rollers as needed will help maintain the optimal function of your garage door.

Installing Anti-Vibration Pads

Benefits of Anti-Vibration Pads for Reducing Noise and Vibration Transfer

Installing anti-vibration pads is an effective measure to further reduce noise and vibration transfer in your garage door system. These pads act as a cushion between the motor and the structure, absorbing vibrations that would otherwise be transmitted and amplified through the mounting brackets or ceiling joists. As a result, they help significantly diminish the operational noise, creating a quieter environment inside and outside the garage.

Placing Pads Between the Motor and Mounting Brackets or Ceiling Joists

To install anti-vibration pads, start by positioning the pads between the motor unit of your garage door opener and the mounting brackets or the ceiling joists. This placement helps isolate the motor from the structural components, preventing vibrations from traveling through the hardware and into the building structure. Typically, these pads are made from rubber or other resilient materials that are engineered to withstand the constant movement and pressure from the motor’s operation.

Ensuring Proper Installation to Maximize Noise Reduction

Ensuring the proper installation of anti-vibration pads is crucial for maximizing noise reduction. Begin by turning off the power to the garage door opener to avoid any accidental activation.

Carefully lift the motor slightly to insert the pads between it and the mounting brackets or ceiling joists, ensuring they are securely positioned. Re-tighten any bolts or screws to secure the motor back in place, making sure not to over-tighten as this can compress the pads and reduce their effectiveness.

By following these steps, you can successfully install anti-vibration pads, which will provide a quieter and more efficient operation for your garage door system. To maintain their noise-reducing benefits, regularly check the condition of the pads and replace them as needed.

Insulating the Garage Door

Using Garage Door Insulation Kits to Reduce Noise Transmission

One effective way to reduce noise transmission in your garage is to utilize garage door insulation kits. These kits typically include pre-cut insulation panels or foam inserts that fit neatly within the door’s framework. They are designed to reduce noise and enhance your garage’s energy efficiency, creating a more comfortable environment overall.

Installing Insulation Panels or Foam Inserts on the Inside of the Door

To install insulation panels or foam inserts, start by thoroughly cleaning the inside surface of your garage door to ensure proper adhesion. Next, measure the door sections and cut the insulation to fit. If using foam inserts, you can simply press them into place within the door panels. Use an adhesive or clips provided in the kit to secure insulation panels to the door. Ensure each panel is firmly positioned, covering the entire surface evenly for optimal insulation.

Benefits of Insulation for Both Noise Reduction and Energy Efficiency

Insulating your garage door provides dual benefits. It significantly reduces noise, creating a quieter environment both inside and outside the garage by dampening sound waves. Additionally, insulation improves energy efficiency by maintaining a more consistent temperature inside the garage. This can reduce heating and cooling costs, particularly if the garage is attached to your home. Overall, installing insulation on your garage door is a practical upgrade that enhances comfort and efficiency.

Conclusion

Effectively quieting a noisy garage door involves a combination of targeted strategies and regular maintenance. Utilizing anti-vibration pads and insulation kits significantly reduces operational noise and improves noise and energy efficiency. Ensuring all components are clean, well-lubricated, and properly secured minimizes disturbances and enhances the door’s performance. Upgrading or retrofitting older systems with quieter rollers and modern motors can also yield substantial benefits.

Regular maintenance and professional inspections play a crucial role in preventing noise issues and prolonging the lifespan of your garage door. By staying proactive with routine checks, you can identify and address potential problems early, ensuring a quieter and more reliable operation.

By following these techniques on how to quiet a garage door, you will enjoy a more peaceful and comfortable garage environment. Investing time and effort into maintaining your garage door not only improves functionality but also enhances the overall quality of your living space.

You Can Check It Out to Install T-handle Garage Door Lock.