The camshaft sensor is a crucial component in your vehicle’s engine management system. It monitors the position and speed of the camshaft and sends this information to the car’s engine control unit (ECU). This data allows the engine to function efficiently by ensuring the proper timing of fuel injection, spark, and valve operation.

A faulty camshaft sensor can lead to various performance issues, making it important to identify and address the problem promptly. This guide is designed to help you with how to tell if a camshaft sensor is bad. Understanding the symptoms of a bad camshaft sensor can help you diagnose and resolve the issue before it leads to more significant damage.

What Is a Camshaft Sensor?

A camshaft sensor is an integral part of a vehicle’s engine management system. Its primary function is to monitor the rotation and position of the camshaft. This information is critical for the engine control unit (ECU) to determine the optimal timing for fuel injection and spark, as well as the operation of engine valves. Typically located near the camshaft, this sensor uses either a magnetic or hall-effect mechanism to measure the camshaft’s position. By relaying precise data to the ECU, the camshaft sensor ensures that the engine runs smoothly and efficiently. Without a properly functioning camshaft sensor, the engine’s performance can be compromised, leading to issues such as misfires, stalling, or difficulty starting.

10 Methods How to Tell if a Camshaft Sensor Is Bad

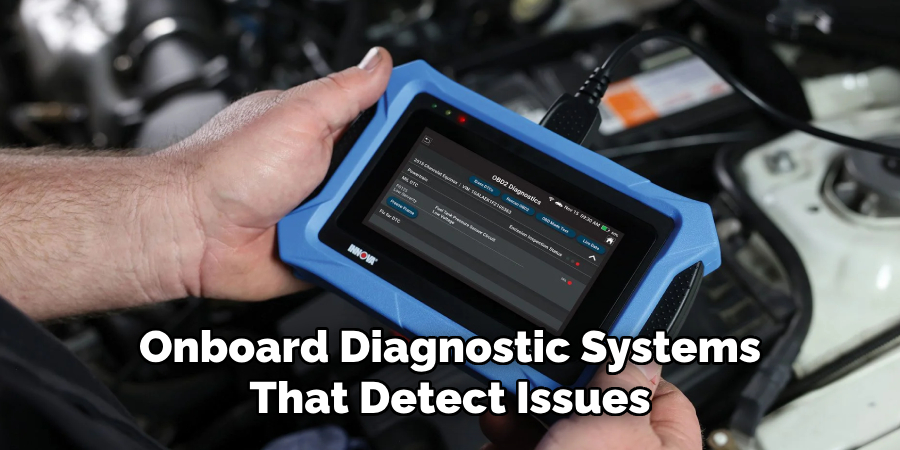

1. Check for Illuminated Check Engine Light

One of the most common signs of a bad camshaft sensor is the illumination of the Check Engine Light (CEL) on your dashboard. Modern vehicles have onboard diagnostic systems that detect issues within the engine, including a malfunctioning camshaft sensor. Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) from the vehicle’s ECU. Codes such as P0340 (Camshaft Position Sensor Circuit Malfunction) or similar indicate a problem with the sensor or its related circuitry. If you don’t own a scanner, most auto parts stores can scan your vehicle for free.

2. Observe Engine Performance Issues

A failing camshaft sensor can cause noticeable engine performance problems, such as rough idling, stalling, or hesitation during acceleration. These issues occur because the ECU relies on accurate data from the sensor to determine the correct timing for fuel injection and ignition. If you experience these symptoms, especially when combined with a CEL, the camshaft sensor is a likely culprit. Pay attention to whether these problems worsen as the engine warms up, as heat can exacerbate sensor failure.

3. Difficulty Starting the Engine

The camshaft sensor helps synchronize the engine’s components during startup. If the sensor is bad, the engine may struggle to start or fail to start altogether. You might notice extended cranking times or the engine turning over without firing. This happens because the ECU cannot correctly identify the camshaft’s position, disrupting the ignition sequence. If this issue is consistent, the sensor should be inspected immediately.

4. Inspect for Erratic or Reduced Engine Power

A faulty camshaft sensor can cause erratic engine behavior, including power surges or drops while driving. You may feel the vehicle lurching or hesitating, particularly during acceleration or while maintaining a steady speed. The sensor’s inconsistent or inaccurate readings disrupt the air-fuel mixture and spark timing, leading to these performance irregularities. Over time, this can strain other engine components, making prompt diagnosis critical.

5. Check for Decreased Fuel Efficiency

Poor fuel economy is another sign of a bad camshaft sensor. When the sensor fails, the ECU may not optimize the air-fuel mixture properly, causing the engine to burn more fuel than necessary. If you notice a significant drop in miles per gallon (MPG) without a change in driving habits, the camshaft sensor may be malfunctioning. This symptom often accompanies other engine performance issues, reinforcing the need for a thorough inspection.

6. Listen for Unusual Engine Sounds

A failing camshaft sensor can cause unusual engine noises, such as misfires or backfires. Misfires occur when the timing of the spark plug firing and fuel injection is off, leading to incomplete combustion in the cylinders. These sounds may be more pronounced during acceleration or when the engine is under load. If you hear these noises, inspect the camshaft sensor and related components to prevent further engine damage.

7. Examine the Sensor for Physical Damage

Perform a visual inspection of the camshaft sensor and its wiring. The sensor is usually located near the camshaft or timing cover and connected to the ECU via electrical wires. Look for visible signs of damage, such as cracks, corrosion, or frayed wires. Physical damage can disrupt the sensor’s ability to transmit accurate data, leading to the aforementioned performance issues. If the sensor or its wiring appears damaged, it should be replaced immediately.

8. Test the Sensor with a Multimeter

To confirm if the camshaft sensor is bad, use a multimeter to test its electrical output. Begin by consulting your vehicle’s repair manual to locate the sensor and identify its signal, power, and ground wires. With the engine off, set the multimeter to the appropriate voltage range and measure the voltage between the signal wire and ground while cranking the engine. A healthy sensor should produce a fluctuating voltage signal, indicating proper function. If there’s no signal or a constant voltage, the sensor is likely faulty.

9. Use an Oscilloscope for a Detailed Diagnosis

An oscilloscope provides a more detailed way to diagnose a camshaft sensor. It displays the sensor’s output as a waveform, allowing you to see its real-time performance. A healthy camshaft sensor will produce a consistent and well-defined waveform pattern. Irregularities, such as missing peaks or inconsistent signals, indicate a malfunction. This method is more advanced but highly accurate, making it a preferred option for professional mechanics or those with access to the necessary equipment.

10. Inspect Related Components for Issues

Sometimes, symptoms that mimic a failing camshaft sensor are caused by issues in related components. For instance, problems with the crankshaft position sensor, timing belt/chain, or ECU can produce similar engine performance issues. Inspect these components for wear or damage. Additionally, check the connector and wiring harness for the camshaft sensor to ensure they are secure and free of corrosion. Resolving issues in these areas may restore proper engine function without replacing the sensor.

Things to Consider

When dealing with a potentially faulty camshaft sensor, there are several factors to keep in mind to ensure a proper diagnosis and repair:

- Vehicle-Specific Information

Different vehicles may have varying locations for the camshaft sensor and unique diagnostic steps. Always refer to your vehicle’s service manual for accurate instructions tailored to your make and model.

- Quality of Replacement Parts

If the camshaft sensor requires replacement, prioritize purchasing high-quality OEM (Original Equipment Manufacturer) parts. Generic or low-cost alternatives may not offer the same reliability or performance.

- Proper Tools for Diagnosis

Tools such as an OBD-II scanner, multimeter, or oscilloscope are essential for accurately diagnosing sensor issues. Using the correct equipment will save time and prevent misdiagnosis.

- Electrical Connections

Check the wiring harness and connectors for any signs of wear, corrosion, or loose connections. Often, the issue may not lie with the sensor itself but rather with its electrical connectivity.

- Related Systems and Components

Since camshaft sensor problems can mimic issues with related components like the crankshaft sensor or timing system, a thorough inspection of these areas is crucial to avoid unnecessary replacements.

Causes of Camshaft Sensor Failure

A camshaft sensor can fail for various reasons, many of which are related to wear, environmental conditions, or electrical issues. Understanding these causes can help with accurate diagnosis and preventive maintenance:

- Physical Damage

External damage such as cracks, impact from debris, or corrosion can impair the sensor’s ability to function. Over time, exposure to extreme temperatures, engine vibrations, and moisture can weaken the sensor’s housing or internal components.

- Electrical Faults

Damaged or frayed wiring, corroded connectors, or poor grounding can disrupt the electrical signals between the camshaft sensor and the ECU. This can lead to errors in engine timing and sensor readings.

- Oil Contamination

Leaking engine oil or excessive buildup around the camshaft sensor can interfere with its operation. This is particularly common in older engines where gasket seals may have deteriorated, allowing oil to seep into sensitive components.

- Wear and Tear

Like many engine components, camshaft sensors are subject to general wear and tear over time. Prolonged exposure to heat, vibration, and continuous use can degrade the sensor’s internal circuitry, impacting its performance.

- Overheating

High engine temperatures can cause the camshaft sensor to overheat, damaging its internal electronics. Prolonged overheating may lead to erratic signal transmission or complete sensor failure.

Conclusion

Diagnosing and addressing issues with a camshaft sensor is vital for maintaining optimal engine performance and efficiency. By following a methodical approach—starting with visual inspections, utilizing diagnostic tools, and considering related components—you can accurately identify and resolve problems. Given the importance of this sensor in synchronizing engine timing, any signs of malfunction should be addressed promptly to prevent further damage or compromised drivability. Thanks for reading, and we hope this has given you some inspiration on how to tell if a camshaft sensor is bad!

About

Safety Fic is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of diy, Safety Fic delves into the art and science of Safety Fic-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Safety Fic) Focus on sustainable design, industry-driven projects, and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in diyfastly.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Safety Fic his insights on indoor design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.