The Throttle Position Sensor (TPS) is vital to your vehicle’s engine management system. It plays a key role in ensuring optimal engine performance by monitoring the position of the throttle valve. The TPS sends this data to the Engine Control Unit (ECU), enabling precise adjustments to the fuel and air mixture based on your driving conditions.

This seamless communication is what allows your vehicle to accelerate smoothly, maintain consistent idling, and perform efficiently. However, a faulty TPS can disrupt this system, leading to poor acceleration, erratic idling, or even engine stalling. Knowing how to tell if your TPS sensor is bad is essential for diagnosing problems early and avoiding potential damage to your engine. By understanding its function and the failure symptoms, you can maintain your vehicle’s reliability and performance over time.

What Is a Throttle Position Sensor (TPS)?

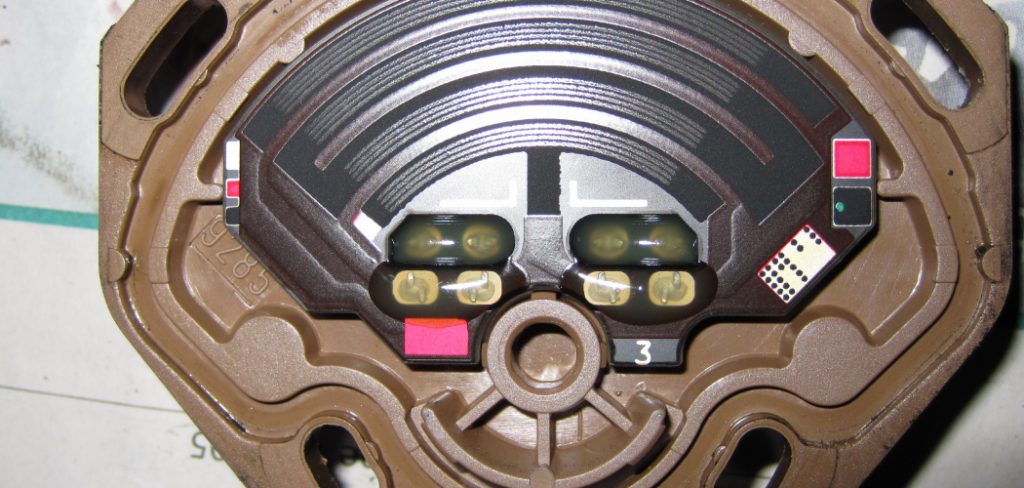

The Throttle Position Sensor (TPS) is an essential part of a vehicle’s engine management system and provides real-time data about the throttle valve’s position. This information is crucial in determining how much air is entering the engine, which the Engine Control Unit (ECU) uses to adjust the air-fuel mixture for efficient performance. Whether you are accelerating,

decelerating, or maintaining a steady speed, the TPS ensures that the engine runs smoothly by facilitating accurate adjustments in response to your driving behavior.

The TPS is typically located on the throttle body, directly attached to the throttle shaft. This position allows it to measure the throttle’s angle precisely and relay the data to the ECU. Without it, the engine cannot properly regulate performance, leading to inefficient operation or even mechanical problems.

Failures in the TPS can occur due to several reasons. Wear and tear over time can degrade its components, causing inaccurate readings or total failure. Electrical issues like faulty wiring or connectivity problems may lead to intermittent operation. Additionally, oil, dirt, or other debris contamination can obstruct the TPS and interfere with its functioning. Recognizing these vulnerabilities is crucial for maintaining optimal engine health and addressing issues proactively.

How to Tell if Your TPS Sensor Is Bad: Symptoms of a Bad TPS

A malfunctioning Throttle Position Sensor (TPS) can lead to various noticeable symptoms that impact engine performance and vehicle drivability.

Engine Performance Issues

A failing TPS often causes hesitation during acceleration or, in some cases, sudden unintended power surges. These issues arise because the engine cannot accurately determine the throttle’s position, leading to improper fuel delivery and air intake adjustments.

Erratic Idle

Another common symptom is erratic engine idling. The engine may idle too high or too low, struggling to maintain a stable RPM. This is usually due to inconsistent or faulty data being sent to the ECU.

Check Engine Light

A bad TPS may trigger the Check Engine Light on your dashboard. This occurs when the ECU detects irregular readings from the TPS, prompting it to store an error code to identify the underlying issue.

Reduced Fuel Economy

Poor throttle data can result in an improper fuel-air ratio, causing the engine to burn more fuel than necessary. This inefficiency leads to a drop in fuel economy and increased emissions over time.

Difficulty Shifting (Automatic Transmissions)

Vehicles with automatic transmissions may experience delayed or harsh shifting patterns. The TPS directly affects the transmission system by providing crucial throttle-related data, and its dysfunction can hinder smooth gear shifts.

Tools Needed for Diagnosis

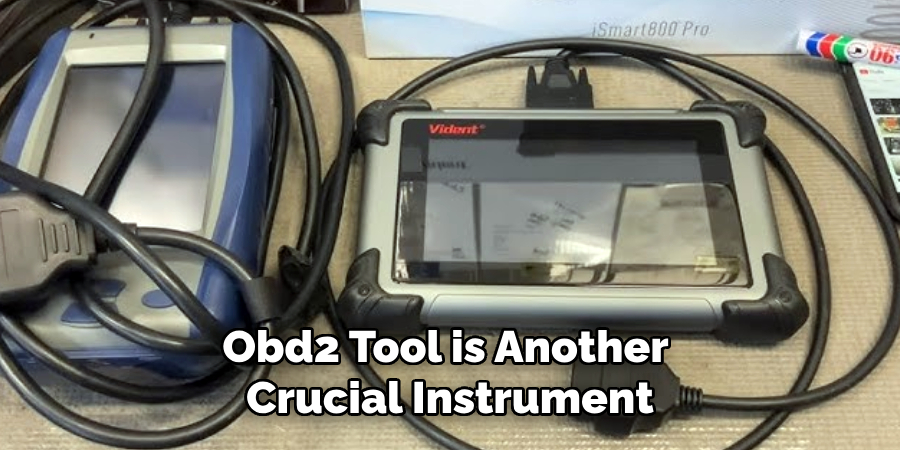

Diagnosing a faulty Throttle Position Sensor (TPS) requires the right tools to accurately identify and address the issue. A multimeter or voltmeter is essential for testing the electrical signals sent by the TPS, ensuring that the voltage output corresponds to the throttle position.

A diagnostic scanner or OBD2 tool is another crucial instrument, as it allows you to read and interpret error codes stored by the vehicle’s ECU, pinpointing the specific problem with the TPS. Additionally, a screwdriver may be necessary for removing the TPS, depending on the sensor’s placement and mounting style in your vehicle. These tools ensure a thorough and precise diagnosis, saving time and preventing unnecessary repairs.

Steps to Test the TPS Sensor

1. Inspect the TPS Visually

Begin by visually inspecting the Throttle Position Sensor (TPS) and its related components. Look for any obvious signs of damage, such as cracked or broken sensor housing, exposed wiring, or loose connections. Pay close attention to the wiring harness and connectors, checking for corrosion, burnt spots, or frayed wires. A visual inspection can often reveal immediate issues that might cause the TPS to malfunction.

2. Use a Multimeter

To thoroughly test the TPS, use a multimeter set to DC voltage. Follow these steps to ensure accurate results:

- Locate the TPS connector, which usually has three terminals (power, signal, and ground). You may need to reference your vehicle’s repair manual to identify these correctly.

- Connect the multimeter’s ground (black) lead to the ground terminal and the positive (red) lead to the signal terminal.

- With the ignition in the ON position (do not start the engine), slowly open the throttle, either manually or by stepping on the accelerator pedal.

- Observe the voltage output on the multimeter. The voltage should start low, typically around 0.5 volts when the throttle is closed, and should increase smoothly to approximately 4.5 volts as the throttle fully opens. Any sudden jumps, drops, or irregular readings may indicate a faulty sensor.

3. Check with a Diagnostic Scanner

Another effective way to test the TPS is by using a diagnostic scanner or OBD2 tool. Here’s how to proceed:

- Plug the scanner into the vehicle’s OBD2 port, typically found under the dashboard.

- Access the live data stream and monitor the TPS readings. The data should show a smooth percentage increase corresponding to the throttle position.

- Check for any Diagnostic Trouble Codes (DTCs) related to the TPS. Common error codes include P0122 (Throttle Position Sensor Circuit Low Input) and P0123 (Throttle Position Sensor Circuit High Input). Note any error codes or anomalies in the live data, as these can help confirm a defective TPS.

By following these steps, you can accurately diagnose issues with the TPS and determine whether it needs adjustment, cleaning, or replacement. This systematic approach ensures a reliable evaluation and helps restore optimal vehicle performance.

Common Issues and Fixes

Understanding common Throttle Position Sensor (TPS) issues can help streamline the troubleshooting process. Below are some frequent problems and their suggested fixes:

Faulty Wiring or Connectors

One of the primary causes of TPS failure is damaged or corroded wiring and connectors. Inspect the wiring harness for frayed wires or loose connections. Replace or repair any damaged components to restore proper communication between the TPS and the Electronic Control Unit (ECU).

Dirty or Sticky Throttle Body

A buildup of dirt or carbon deposits on the throttle body can lead to inaccurate TPS readings or reduced throttle response. Cleaning the throttle body using an appropriate cleaner can effectively resolve this issue, ensuring smooth sensor operation and optimal airflow.

Sensor Calibration Problems

After installing a new TPS, some vehicles may require recalibration to ensure the sensor accurately measures the throttle position. Follow the vehicle manufacturer’s instructions or use a diagnostic scanner to perform the calibration process if needed.

By addressing these issues promptly, you can prevent further complications and maintain a consistent driving experience. A well-maintained TPS and throttle system contribute significantly to overall engine performance and fuel efficiency.

When to Replace the TPS

Replacing the TPS becomes essential under specific circumstances to ensure the performance and reliability of your vehicle. One key indicator is persistent symptoms, such as irregular voltage readings or recurring error codes, even after cleaning and testing the sensor. If these issues remain unresolved, the TPS may be faulty and require replacement.

Another factor to consider is the age and wear of the sensor. Throttle Position Sensors typically last between 60,000 and 100,000 miles, though this can vary depending on your driving conditions and maintenance habits. Over time, wear and tear can compromise the TPS’s accuracy and functionality.

Lastly, replacing the TPS is a cost-effective solution to avoid more severe engine issues. Delaying replacement could result in poor fuel efficiency, unstable idling, or unexpected acceleration problems, potentially leading to more expensive repairs. Proactive replacement ensures smooth engine operation and optimal performance.

Conclusion

The Throttle Position Sensor (TPS) is critical in ensuring your engine performs smoothly and efficiently. Understanding how to tell if your TPS sensor is bad can save you from costly repairs. Key signs of a failing TPS include irregular voltage readings, error codes, poor fuel economy, rough idling, or sudden acceleration issues. Diagnosing a faulty TPS involves visual inspections, multimeter testing, and OBD2 scanning tools.

Addressing a faulty sensor promptly is essential to prevent long-term engine damage and maintain optimal vehicle performance. Regular maintenance can further extend the life of this vital component.

About

Safety Fic is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of diy, Safety Fic delves into the art and science of Safety Fic-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Safety Fic) Focus on sustainable design, industry-driven projects, and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in diyfastly.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Safety Fic his insights on indoor design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.