Ensuring the proper functionality of a fire sprinkler system is essential for the safety of any building’s occupants. Regular testing and maintenance are critical to confirm that the system will operate as intended during an emergency.

This guide on how to test fire sprinkler system will outline the steps necessary to test a fire sprinkler system, including inspecting the components, performing water flow tests, and documenting the results for compliance with safety standards.

By following these procedures, building owners and facility managers can help protect lives and property while adhering to fire safety regulations.

What is a Fire Sprinkler System?

A fire sprinkler system is an active fire protection measure designed to suppress or extinguish fires in buildings. It consists of a network of pipes connected to a water supply and fitted with sprinkler heads that spray water when triggered by heat. The system’s goal is to control the spread of fire before it becomes uncontrollable while also providing occupants with enough time to evacuate safely.

You will find fire sprinkler systems in various types of buildings, including commercial, residential, and industrial properties. They are considered the most effective method for controlling fires and reducing potential damage.

Why is Testing a Fire Sprinkler System Important?

Testing a fire sprinkler system is crucial because it ensures that all components are working correctly. It is not enough to have a system in place; regular testing helps identify any issues that may prevent it from functioning as intended during an emergency.

Additionally, fire sprinkler systems must comply with local and national safety regulations. By performing regular tests and documenting the results, building owners can demonstrate their compliance with these standards.

Testing also provides peace of mind for building occupants, knowing that the fire sprinkler system is regularly checked and maintained for functionality.

Needed Materials

Before testing a fire sprinkler system, gather all necessary materials and equipment. These include:

Ladder or Scaffolding (if Needed):

Depending on the height of the sprinkler heads, you may need a ladder or scaffolding to access them for testing and inspection.

Protective Equipment:

Safety goggles, gloves, and other protective equipment should be worn during the testing process to prevent injury.

Water Flow Test Kit:

This kit includes a pressure gauge, hose, valve, and flow measurement device. It is used to measure water pressure and flow rate from the sprinkler system.

Inspection Checklist:

Have an inspection checklist on hand to ensure that all components are thoroughly examined during the testing process.

7 Steps on How to Test Fire Sprinkler System

Step 1: Notify Occupants

Before commencing any testing procedures on the fire sprinkler system, it’s imperative to notify all building occupants. Informing everyone in advance helps prevent confusion and panic during the test. Post notices in common areas and send out emails or other communications to ensure that everyone is aware of the scheduled test.

Make clear that the forthcoming alarms and water flow are part of a routine check rather than an actual emergency. This step is crucial for maintaining safety and minimizing interruptions to daily activities.

Step 2: Review the Inspection Checklist

Before you begin the physical inspection and testing of the fire sprinkler system, take the time to review the inspection checklist thoroughly. This checklist will guide you through all the necessary components and areas that must be examined to ensure comprehensive testing. Items on the checklist typically include checking sprinkler heads for any signs of damage or blockage, inspecting control valves for proper positioning and functionality, and verifying that the alarm system is operational.

Reviewing the checklist ensures no critical step is overlooked during the inspection. It also provides a systematic approach to documenting the condition and performance of each component, which is essential for maintaining accurate records and compliance with safety standards. Make sure to have the checklist readily accessible throughout the inspection process so that you can reference it as needed. This preparation helps streamline the inspection and ensures a methodical and thorough approach to testing the fire sprinkler system.

Step 3: Inspect the Sprinkler Heads

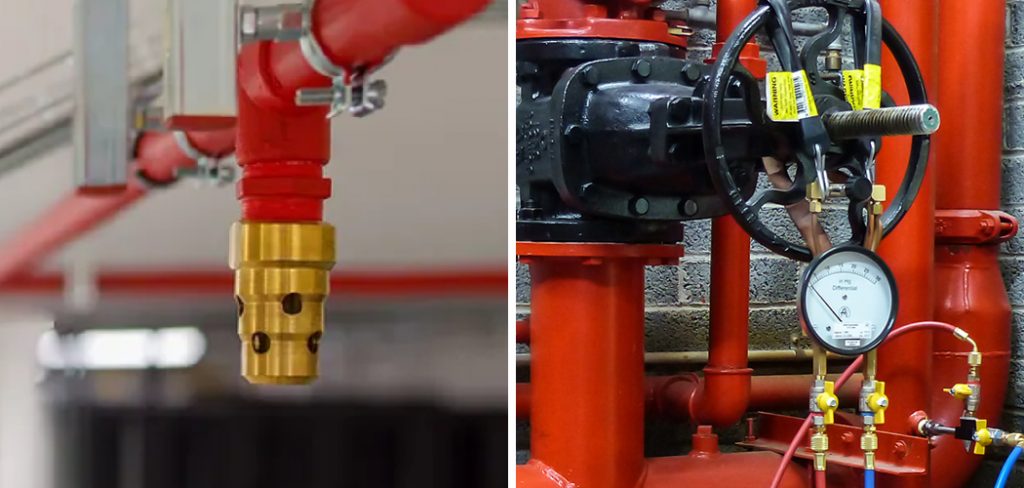

The first component to inspect is the sprinkler heads. These are the parts that will activate during a fire and spray water onto the flames. Examine each sprinkler head for any signs of physical damage, such as dents or corrosion, which can affect functionality. Look for any obstructions near the heads, such as debris or furniture, and ensure they have proper clearance.

Next, check for blockages within the sprinkler heads by removing them and inspecting the openings for any buildup or clogs that may prevent water from flowing correctly. If there are any visible blockages, clean the heads thoroughly before replacing them. Proper water flow is crucial for the system’s effectiveness, and this step helps identify and remove potential obstructions that may hinder it.

Step 4: Check Control Valves

Control valves are critical components of a fire sprinkler system, regulating the water flow and ensuring that the system activates correctly during an emergency. Begin by locating all control valves within the building, which are typically found in designated valve rooms or riser areas.

Inspect each valve to ensure it is in the proper open position and that there are no visible signs of tampering or damage. Closed or partially closed valves can prevent water from reaching the sprinkler heads, rendering the system ineffective. Verify the valves’ status by observing the position indicators, which should clearly show whether the valve is open or closed.

Step 5: Monitor the Alarm System

Fire sprinkler systems are equipped with alarm systems that activate when heat from a fire triggers the sprinkler heads. During testing, it’s essential to ensure that these alarms are functioning correctly and can be heard throughout the building. Go through each area of the building and listen for the alarm sound, checking its volume and clarity.

If there is no audible alarm, make sure to address this issue immediately by contacting a professional technician to repair or replace any faulty components.

Step 6: Measure Water Pressure and Flow Rate

Using a water flow test kit, measure the pressure and flow rate of the water coming from the sprinkler system. This step provides critical information on the system’s performance, including identifying any potential obstructions or issues that may affect its effectiveness during a fire.

Follow the kit’s instructions to connect it to a test valve on the system, typically located near the main riser. Once connected, open the valve and record both the pressure and flow rate measurements from the gauge.

Step 7: Record and Document Results

After completing the measurements of the water pressure and flow rate, it’s crucial to meticulously record and document all results. Start by noting the date and time of the test to create a clear timeline for future reference. Use a standardized form or digital log to input the recorded pressure and flow rate values alongside any observations or anomalies noticed during the test.

Each reading should be compared against the system’s baseline expectations to verify whether it meets the required standards. Highlight any deviations and make detailed notes about potential issues, such as reduced water pressure or flow rate that doesn’t align with the system’s specifications. Furthermore, document the condition of all inspected components, including sprinkler heads, control valves, and the alarm system. These records are crucial for tracking the system’s performance over time and identifying any recurring problems that may require immediate attention.

Frequently Asked Questions

Q: How Often Should a Fire Sprinkler System Be Tested?

A: The National Fire Protection Association (NFPA) recommends that fire sprinkler systems undergo a full inspection and testing every five years. However, it’s essential to check with your local fire department or building code regulations for specific requirements and frequency.

Q: Can I Test My Fire Sprinkler System Myself?

A: While basic visual inspections can be done by building owners or facility managers, a comprehensive inspection and testing of the system should only be performed by trained professionals. They have the necessary equipment and expertise to identify any potential issues accurately and ensure compliance with safety standards.

Q: What Happens if a Component Fails During Testing?

A: If any component fails during testing, it’s crucial to take immediate action to address the issue. Depending on the severity of the problem, a professional technician may need to repair or replace the faulty component. It’s essential to document any failures and their solutions for future reference.

With these steps and guidelines on how to test fire sprinkler system, you can perform a proper inspection and testing of your fire sprinkler system. Regular maintenance and testing are crucial for ensuring the system’s effectiveness in case of a fire emergency. If you encounter any issues or have concerns, it’s always best to consult a professional technician for further assistance.

Conclusion

Regularly inspecting and testing fire sprinkler systems is essential for maintaining their effectiveness in protecting buildings and occupants from fires. By following the seven steps on how to test fire sprinkler system outlined above, you can ensure a thorough and comprehensive inspection that addresses all critical components of the system.

Remember to review the inspection checklist beforehand, complete each step carefully, and accurately record all results. Scheduled inspections not only help maintain safety but also provide peace of mind, knowing that your building’s fire protection system is operational and ready for any emergency. So, it is crucial to make regular inspections a priority to ensure the system’s proper functioning and safeguard against potential hazards.

About

Safety Fic is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of diy, Safety Fic delves into the art and science of Safety Fic-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Safety Fic) Focus on sustainable design, industry-driven projects, and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in diyfastly.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Safety Fic his insights on indoor design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.