There are several reasons that make camlock a great choice for locking up your valuables. Camlocks are simple, reliable, and easy to use with the right key. They can also provide greater security than other types of locks by being harder to pick or break into. Camlocks come in different sizes and shapes so you can easily find one that fits your needs.

When it comes to securing two pieces together, camlock connectors are an excellent choice. Camlocks offer a quick and simple way to make a secure connection between two items, such as pipes or hoses. This type of connector can be used in many applications, from industrial work to home improvement projects. In this blog post, You will learn in detail how to use camlock.

Step-by-step Instructions for How to Use Camlock

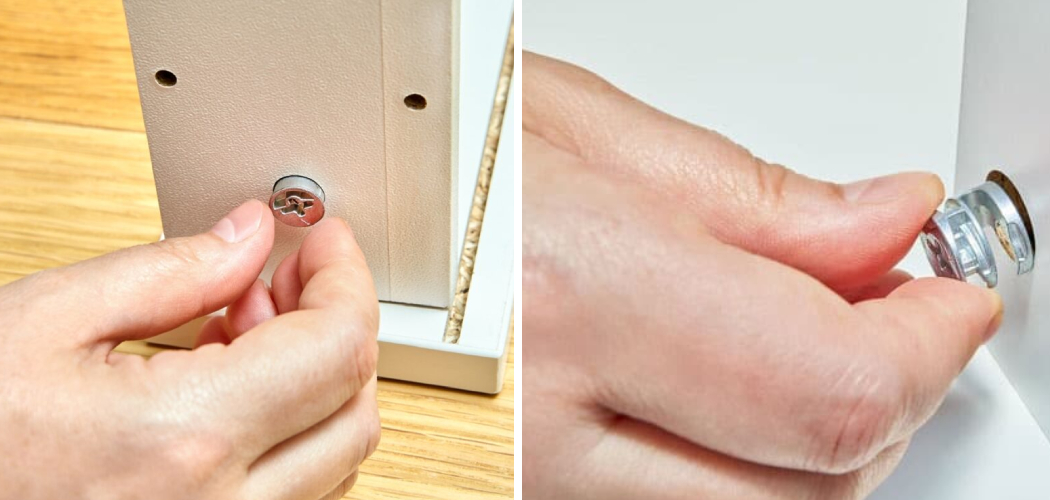

Step 1: Inspect the Camlock

Make sure all the necessary parts are present and in good condition. Check for any signs of wear or damage, such as broken pieces or bent pins. Use a tape measure to take measurements of the area where you plan to install the Camlock. Then mark off these measurements on the wall with a pencil or marker.

Step 2: Pre-drill and Countersink Holes

Using an appropriate drill bit, pre-drill the holes in the wall where you made your marks. Be sure to use a countersink bit to create recesses for the Camlock’s screws. Insert anchor plugs into the pre-drilled holes. Tap them in with a hammer until they are flush against the wall.

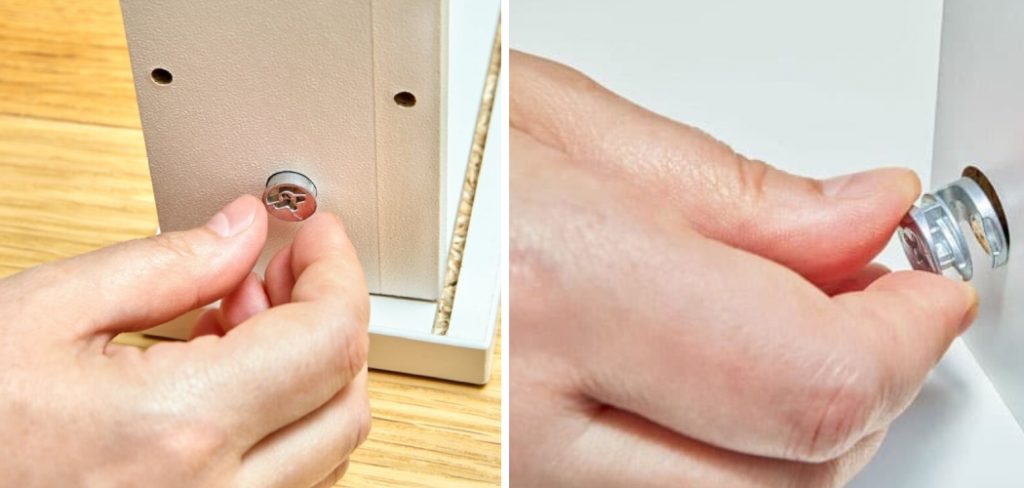

Step 3: Insert Camlock

Slide the Camlock into place, making sure that the notches align properly and that it is seated firmly against the surface of the wall. Using a screwdriver, secure the Camlock to the wall by inserting the screws into the anchor plugs.

Step 4: Line up and Secure Connecting Pieces

If you are using the Camlock with other locking or latching mechanisms, line them up properly and secure them together with screws if necessary. Once everything is in place, test to make sure that the Camlock operates as it should.

Step 5: Insert Key or Combination Code

After confirming the Camlock is properly installed and functioning, insert the appropriate key or combination code to lock it in place. You’re now ready to enjoy a secure environment with your newly installed Camlock!

For finishing touches and extra security, you can add additional locking mechanisms to your Camlock setup. Be sure to research the best practices for other Camlock accessories and make sure that all pieces are firmly secured in place before use.

Safety Tips for How to Use Camlock

- Make sure to wear the necessary protection gear and safety equipment such as gloves, goggles, etc. when working with camlock fasteners.

- Check the camlocks for any signs of damage or defects before use them; never use a broken or damaged camlock for any purpose.

- Use only compatible components when assembling or installing camlock systems, including the right type of camlock and its corresponding hardware.

- Follow manufacturer instructions for any special assembly requirements or safety precautions when assembling your camlock system.

- Always work with trained professionals to install and/or maintain your camlock systems, as they are more knowledgeable in this field.

- Beware of potential slipping hazards; make sure to secure the camlock in place with screws or other mounting materials.

- Never attempt to open a camlock without the correct key; this could cause permanent damage to the camlock system and render it useless.

In addition, always inspect your camlocks periodically for any signs of corrosion, wear-and-tear, or tampering that can affect their functionality and safety. Implement preventive maintenance measures for your camlocks on a regular basis to ensure their proper functioning and longevity.

Are There Any Warning Signs That Indicate When a Camlock Connection Should Be Checked or Replaced?

Yes, there are warning signs that indicate when a camlock connection should be checked or replaced. If the camlock connection is broken or worn out, it may not seal correctly and can cause potential safety hazards. It is always important to check the condition of your camlock connection before making any changes to ensure that it is in good condition and will not fail under pressure.

Additionally, it can be helpful to inspect the camlock connection regularly to ensure that any wear and tear is addressed before it causes a safety concern.If you notice any unusual signs or sounds coming from your camlock connection, such as an odd smell or rattling sound, it is best to have it inspected by a professional as soon as possible.

Additionally, if the camlock connection appears to be loose or does not seem to fit correctly, it is best to replace it immediately. Taking action promptly can help you avoid any potential safety hazards and ensure that your camlock connection is secure and functioning properly.

What is the Best Way to Maintain and Inspect Camlock Connections Over Time?

Regular maintenance and inspection of Camlock connections will help to ensure that they are in good working order for a long time. This can be done by periodically checking the tightness of the connection, as well as inspecting for signs of leaks or other damage.

It is also important to ensure that any dirt, debris or foreign objects are removed from the area around the connection in order to ensure that the camlock connection stays secure and sealed.Additionally, it is important to regularly lubricate the moving parts of the camlock connection with a food-grade lubricant in order to keep it functioning correctly over time.

If any major damage or wear is noticed, it can often be repaired by replacing certain components or tightening up the connection. Taking these steps will help to ensure that your camlock connection is secure and functioning correctly.

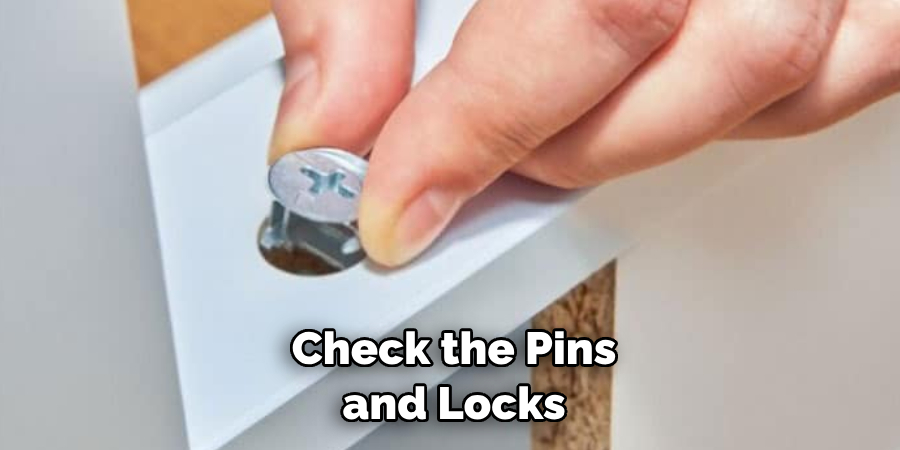

How Often Should You Check Your Camlocks for Wear and Tear?

It’s important to check your camlocks for wear and tear regularly. Check the pins and locks at least once a year or after any heavy use, such as moving large pieces of equipment or furniture that could potentially put strain on the camlocks. Regularly inspecting your camlock will ensure it is kept in good working order and can safely support whatever you are using it for.

If you notice any signs of wear and tear, such as loose pins or locks that don’t seem to fit as tightly as they used to, then it is best to replace the camlock.This will ensure that your camlock remains secure and prevent any accidents from occurring due to a faulty lock or pin. Additionally, make sure to regularly clean out any dirt and debris that may have built up in the camlock.

This will ensure that the lock is working properly and not impeding its effectiveness. It’s also important to check other parts of your camlock regularly, such as the springs which keep the pins in place. If the springs are worn or damaged then you should replace them immediately to prevent any accidents from happening.

Are There Any Common Mistakes to Avoid When Using Camlock Systems?

When using camlock systems, it is important to keep a few common mistakes in mind in order to ensure that the system works properly. One of the most common mistakes is forgetting to tighten the connector after connecting two pieces together. It is essential to make sure the connector is tightened fully so that there are no leaks or other issues with the system.

Another common mistake is using the wrong size connector for the job. Make sure that you are using the right size camlock connectors to ensure a secure connection between two pieces of equipment or furniture. Finally, make sure that any parts you buy for your camlock system are certified and made from high-quality materials in order to ensure that they will last a long time and perform safely and effectively.

Are There Any Special Instructions for Disassembling and Reassembling Camlock Connectors?

Yes, it is important to follow special instructions when disassembling and reassembling Camlock connectors. To begin, you should always make sure that the parts are thoroughly cleaned before removal or installation. This ensures that any dirt or debris will be removed from the connector before attempting to unlock it. Next, ensure that all gaskets and seals are in good condition before attempting to reassemble the connector.

Finally, make sure to grease all of the parts that will be assembled together before placing them into the connector. This ensures a secure and tight connection between two pieces of equipment or furniture. By following these steps, you can ensure that your Camlock connectors remain strong and secure during use. Additionally, you can avoid accidents and damage caused by improper assembly or installation.

What Are the Benefits of Using a Camlock System?

There are many benefits to using camlock systems. Firstly, they provide an incredibly secure connection between two pieces of equipment or furniture. This makes them ideal for use in a variety of settings, such as medical facilities, warehouses, and industrial sites. Additionally, camlock systems are incredibly easy to install and disassemble, making them perfect for situations where time is of the essence.

Finally, camlock connectors come in a wide variety of sizes and designs to suit any application or situation. This makes them highly versatile and ensures that you can find the perfect connector for your needs. The use of camlock systems is an excellent way to ensure that two pieces of equipment or furniture are securely connected, making it a popular choice in many industries.

Conclusion

One of the main disadvantages with using camlocks is that they are not designed for long-term use. The repeated action of connecting and disconnecting can cause wear on the surface of the fastener which could lead to failure over time. Additionally, dirt and debris can get trapped in the threads or crevices of the camlock, leading to jamming or difficulty in opening and closing.

In conclusion, camlock is an incredibly useful fastening mechanism that can be used in many ways to secure items together. Its versatility makes it a great choice for projects where different materials need to be locked together. Whether you need to securely connect two pieces of metal, plastic or another material, camlock can offer the perfect solution.

With a little bit of know-how and some basic tools, you can install and use camlock in no time. I hope this article has been beneficial for learning how to use camlock. Make Sure the precautionary measures are followed chronologically.